Choosing which packaging tests reduce risk is one of the most important decisions packaging engineers and quality teams make before commercial release. Packaging failures rarely come from a lack of testing. They come from choosing the wrong test for the real distribution environment.

Many packages pass a standard test and still fail in the field. That usually means the test validated compliance, not risk.

Why Some Packaging Tests Do Not Reduce Risk

Most packaging tests are designed to be repeatable and standardized. That is necessary for compliance, but it does not automatically translate to real-world protection.

Risk is driven by how your product is actually shipped. Parcel versus LTL. Unitized versus palletized. One distribution cycle versus multiple. If the test does not reflect those conditions, it may only confirm that a minimum requirement was met.

Which Packaging Tests Reduce Risk in Parcel Distribution

For parcel shipments, which packaging tests reduce risk comes down to selecting the right ISTA procedure.

- ISTA 1A is a basic integrity test. It can identify obvious weaknesses but does not simulate real carrier hazards.

- ISTA 2A adds conditioning and sequence changes that better represent parcel handling.

- ISTA 3A is designed to simulate small parcel delivery with defined drop heights, vibration profiles, and compression forces.

If you are shipping through parcel networks and experiencing damage, ISTA 3A generally provides the highest risk reduction because it models cumulative handling events rather than isolated impacts.

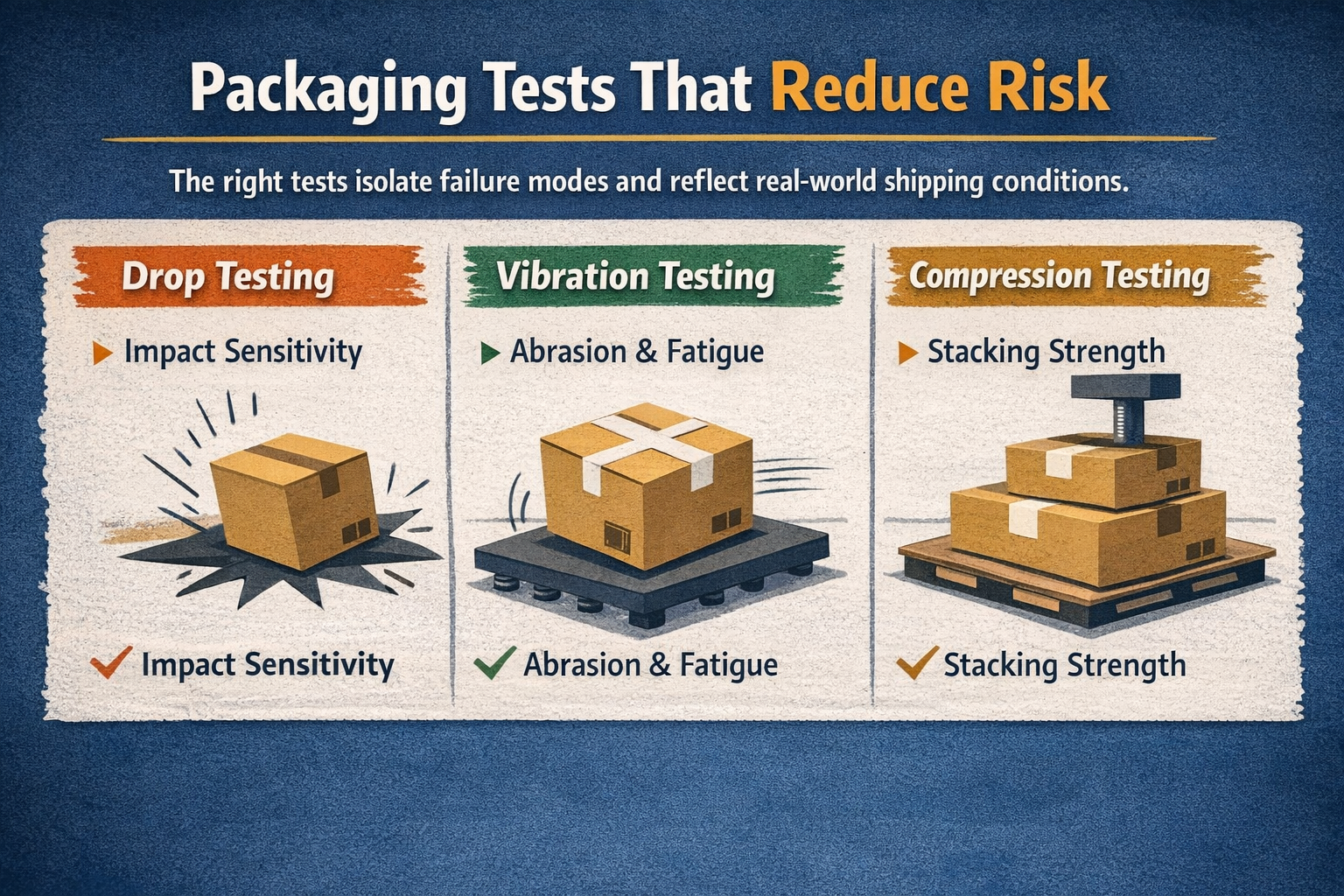

ASTM Packaging Tests That Reduce Risk by Isolating Failure Modes

ASTM methods are most effective when you already know what you are trying to stress.

Common examples include:

- ASTM drop testing to isolate impact sensitivity

- ASTM vibration testing to evaluate loosening, abrasion, or fatigue

- ASTM compression testing to assess stacking and top load risk

These tests reduce risk when they are selected intentionally. Running them in isolation without understanding the failure mode often results in data that is technically valid but operationally incomplete.

Environmental Conditioning Is Often the Missing Link

Environmental exposure is one of the most underestimated sources of packaging failure.

Heat, cold, and humidity can weaken corrugate, soften adhesives, or change material behavior before mechanical testing even begins. Conditioning protocols aligned with ASTM environmental standards are often what turn a passing package into a failing one.

If your product ships through uncontrolled environments or sits in transit for extended periods, conditioning is not optional. It is central to determining which packaging tests reduce risk.

Tests That Check a Box But Do Not Lower Risk

Some tests are run because they are requested, not because they reflect reality.

Examples include:

- Using ISTA 1A for high-value or fragile products

- Skipping vibration testing when damage occurs without visible drops

- Ignoring environmental conditioning for products sensitive to moisture or heat

These tests may satisfy documentation requirements, but they do little to prevent damage, returns, or field failures.

Practical Takeaway for Engineers and Quality Teams

The tests that reduce risk are the ones that reflect how your product is actually handled, stored, and transported. Compliance alone does not protect products. Alignment does.

If you are unsure which packaging tests reduce risk for your product, the right answer usually comes from reviewing your distribution profile before selecting a test standard.

Next Step

If you want help selecting the correct test based on real shipping conditions, ask which test is right for your product. A short risk review often prevents months of rework after launch.