by Amber Livesey | Feb 2, 2026 | Testing

Packaging testing process failures when testing is too late rarely occur because tests are performed incorrectly.They occur because testing is introduced too late, after packaging design decisions have already been finalized. When testing is treated as a final...

by Amber Livesey | Jan 27, 2026 | Test Selection

Packaging teams often assume that passing a standard test means their product is protected. The reality is more complicated. ISTA vs ASTM testing is not a matter of which standard is better, but whether either standard actually reflects the real risks your package...

by Amber Livesey | Jan 20, 2026 | Cold Weather

Many packaging systems perform well in controlled conditions, yet fail once winter shipping begins.Cold weather packaging testing is often treated as optional, even for products that move through uncontrolled truck routes, outdoor transfer points, and regional hubs...

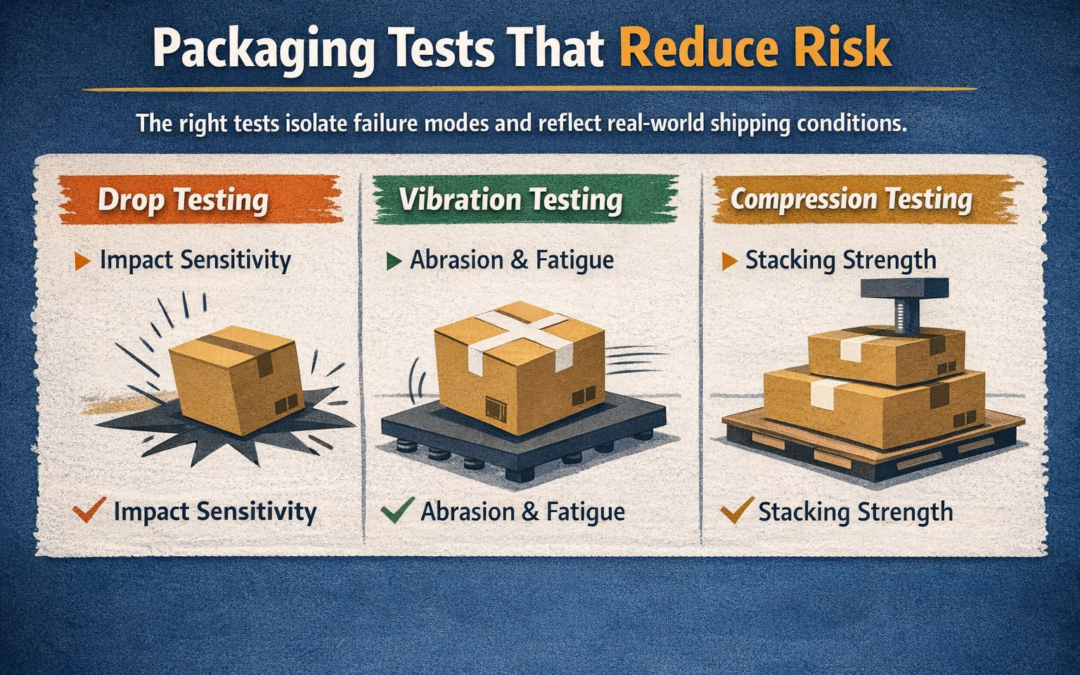

by Amber Livesey | Jan 14, 2026 | Test Selection

Choosing which packaging tests reduce risk is one of the most important decisions packaging engineers and quality teams make before commercial release. Packaging failures rarely come from a lack of testing. They come from choosing the wrong test for the real...

by Amber Livesey | Jan 7, 2026 | Testing

Packaging failures after peak season often surprise teams because the packaging already passed required lab tests. Yet once shipping volume increases, handling becomes less controlled, and transit times extend, damage appears that was never seen during validation. In...