by Amber Livesey | Feb 2, 2026 | Testing

Packaging testing process failures when testing is too late rarely occur because tests are performed incorrectly.They occur because testing is introduced too late, after packaging design decisions have already been finalized. When testing is treated as a final...

by Amber Livesey | Jan 27, 2026 | Test Selection

Packaging teams often assume that passing a standard test means their product is protected. The reality is more complicated. ISTA vs ASTM testing is not a matter of which standard is better, but whether either standard actually reflects the real risks your package...

by Amber Livesey | Jan 20, 2026 | Cold Weather

Many packaging systems perform well in controlled conditions, yet fail once winter shipping begins.Cold weather packaging testing is often treated as optional, even for products that move through uncontrolled truck routes, outdoor transfer points, and regional hubs...

by Amber Livesey | Jan 14, 2026 | Test Selection

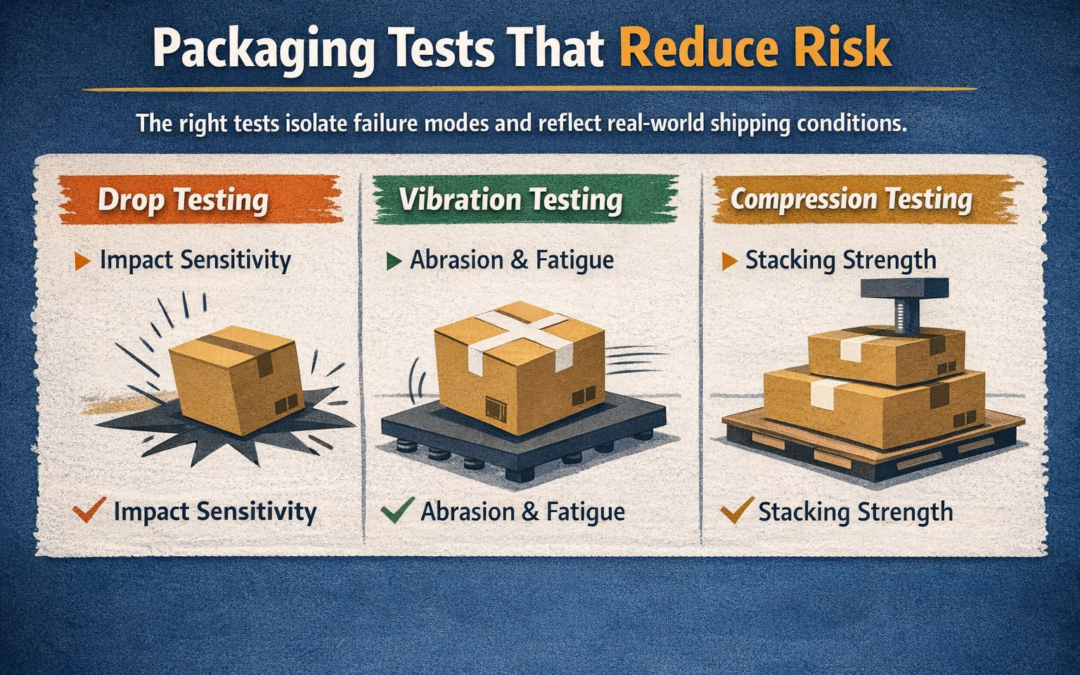

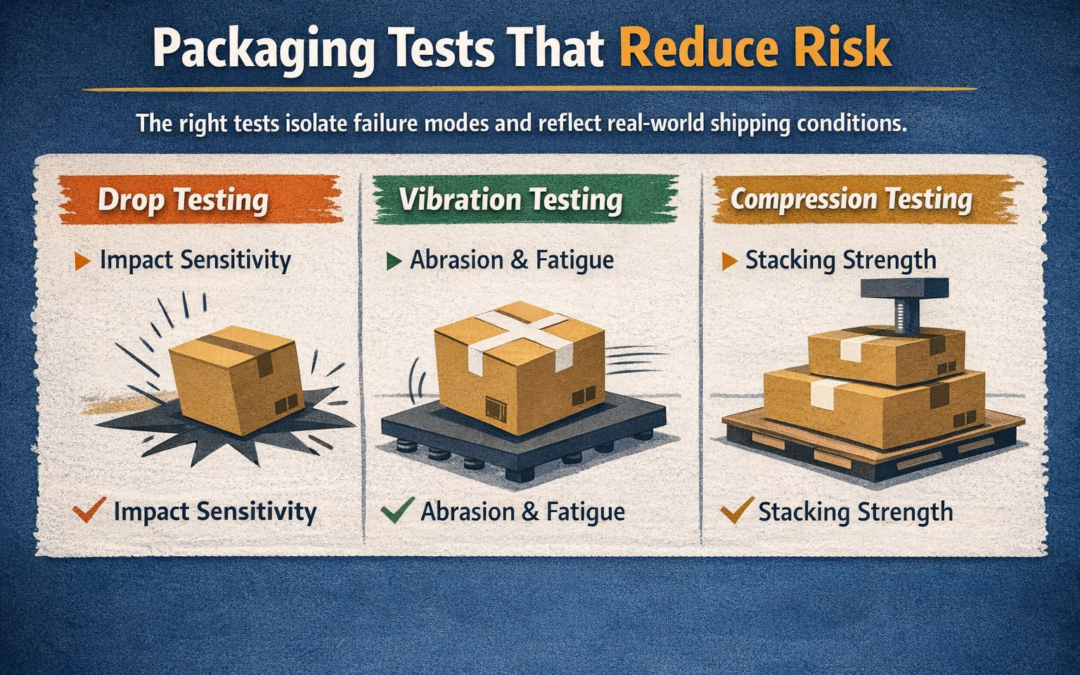

Choosing which packaging tests reduce risk is one of the most important decisions packaging engineers and quality teams make before commercial release. Packaging failures rarely come from a lack of testing. They come from choosing the wrong test for the real...

by Amber Livesey | Jan 7, 2026 | Testing

Packaging failures after peak season often surprise teams because the packaging already passed required lab tests. Yet once shipping volume increases, handling becomes less controlled, and transit times extend, damage appears that was never seen during validation. In...

by Amber Livesey | Jan 2, 2026 | Testing

Peak season shipping has a way of clarifying things, especially when packaging teams begin planning how to re-test packaging in Q1. By the time volumes slow down, most teams already know where the cracks showed up. Damage claims, seal issues, pallet instability,...

by Amber Livesey | Dec 17, 2025 | Testing

Peak season packaging failures are rarely caused by skipped testing. Instead, high shipping volume exposes stress combinations that standard packaging validation doesn’t fully replicate. Higher volume means more handling, taller stacking, faster movement, and less...

by Amber Livesey | Dec 11, 2025 | Temperature Testing

During a recent endurance trek through Patagonia, Perry (gh Testing’s President) felt extreme temperature swings that changed within minutes. The morning started below freezing. By afternoon, the rocks were radiating heat and the wind shifted the temperature...

by Amber Livesey | Dec 4, 2025 | Test Selection

Choosing the right packaging test is one of the most important decisions in any validation process. It affects how well your product survives distribution, how quickly you can launch, and whether you meet the expectations of retailers and carriers. With multiple ISTA...

by Amber Livesey | Nov 12, 2025 | Lowering Cost

If you design or validate packaging, you already know the challenge: reduce material, maintain protection, and keep margins healthy. gh Testing Product Testing and Consulting helps packaging engineers, quality managers, and operations leaders do exactly that through...